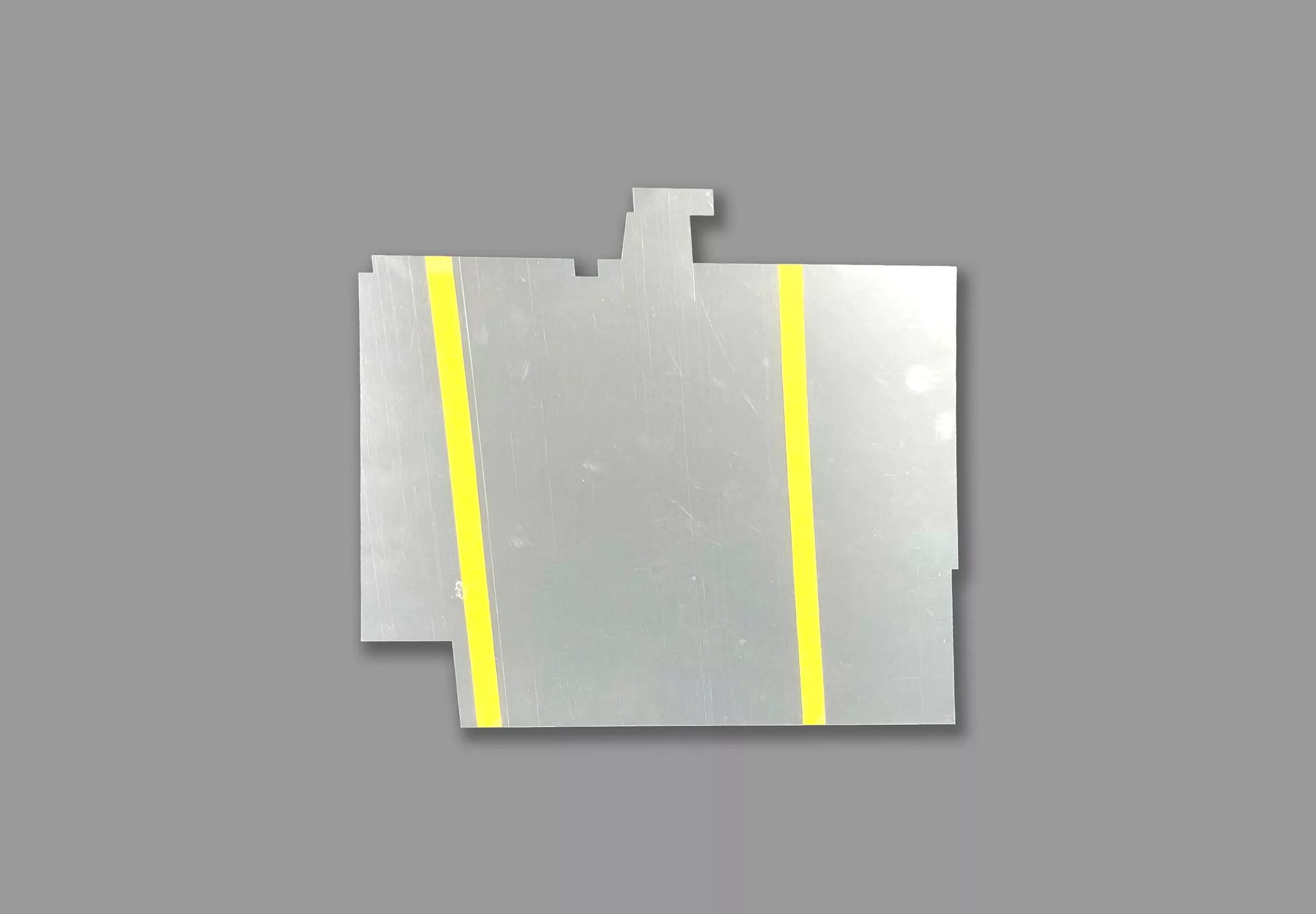

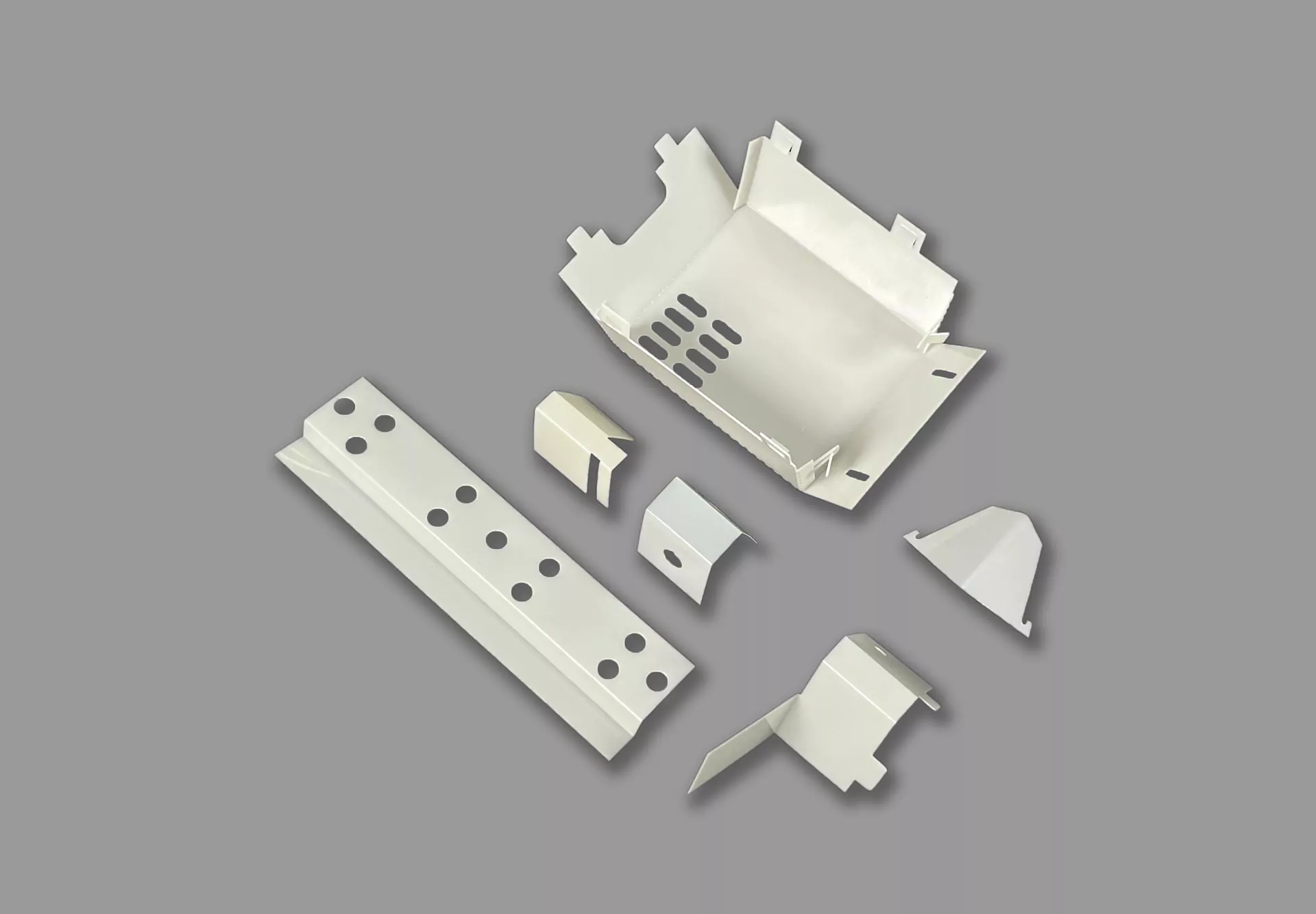

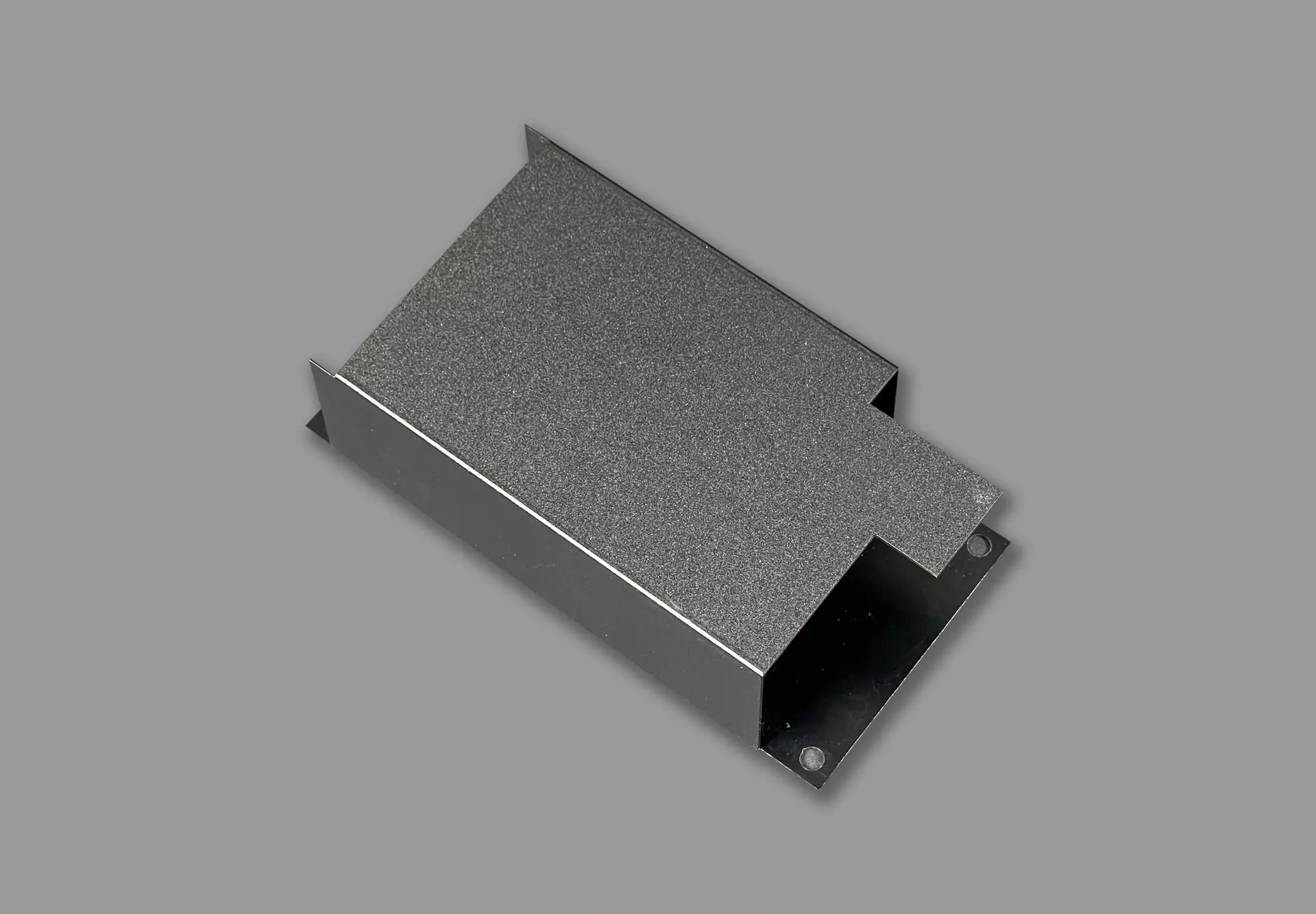

Foil stampings and molded parts

We make the right impression

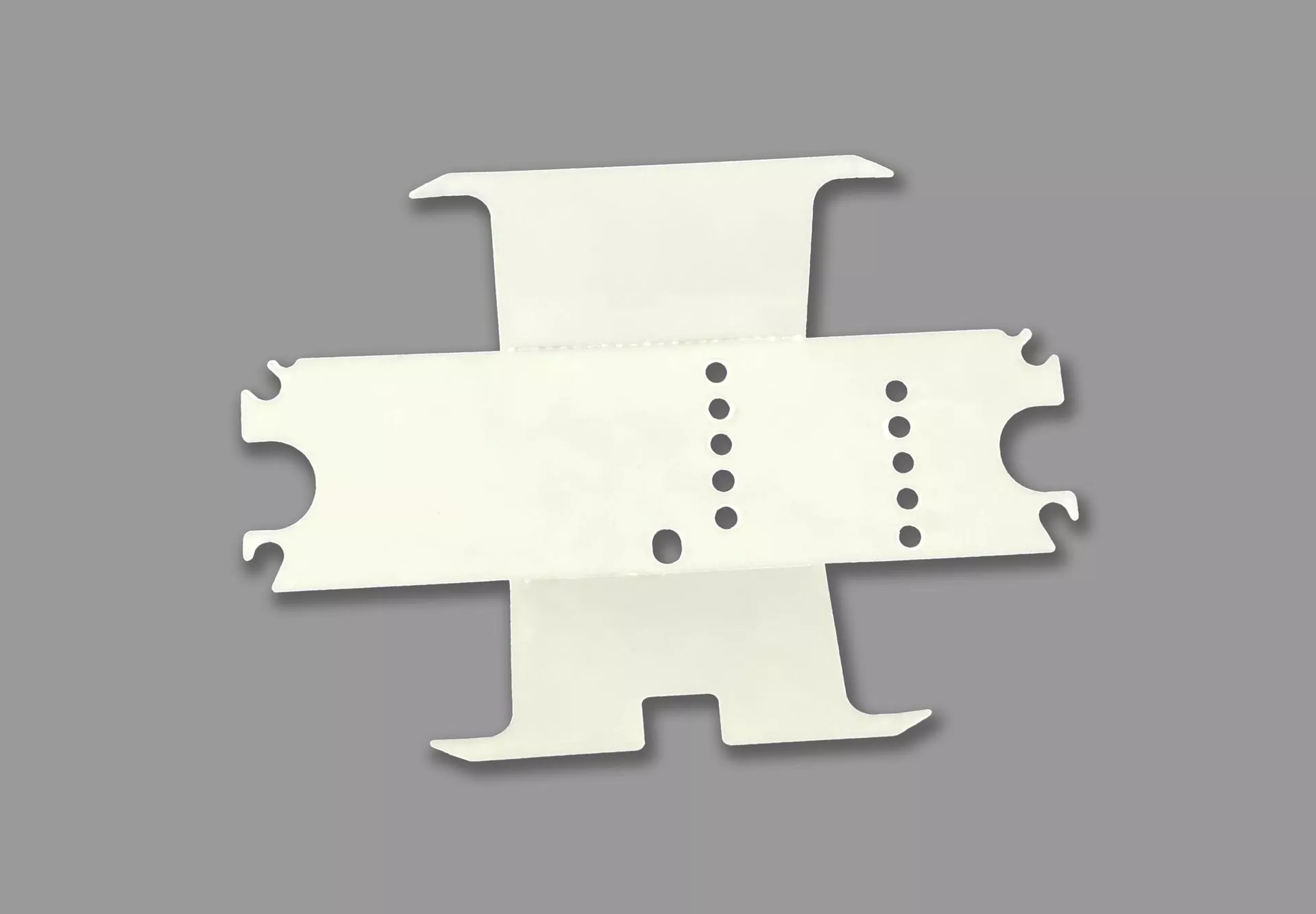

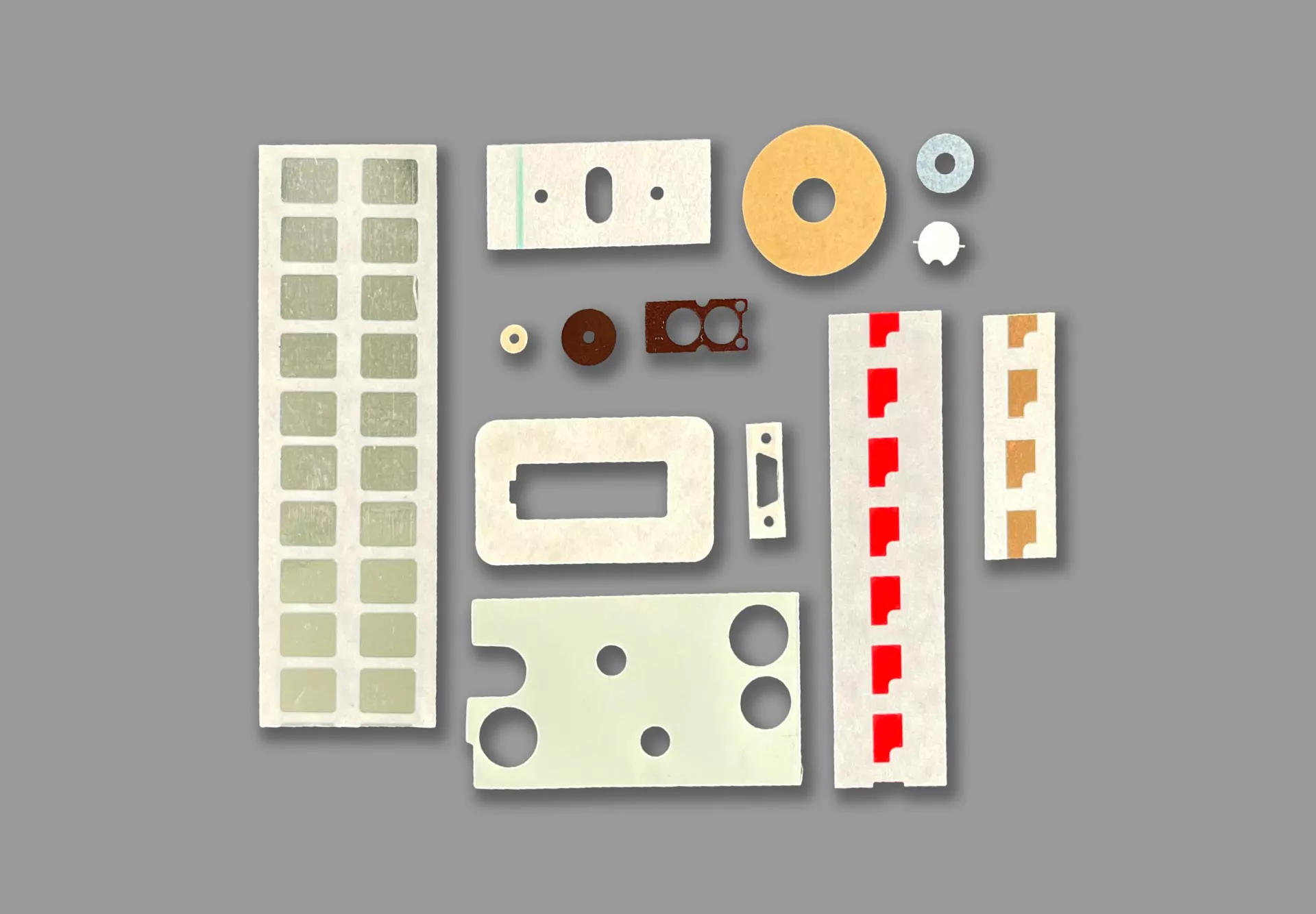

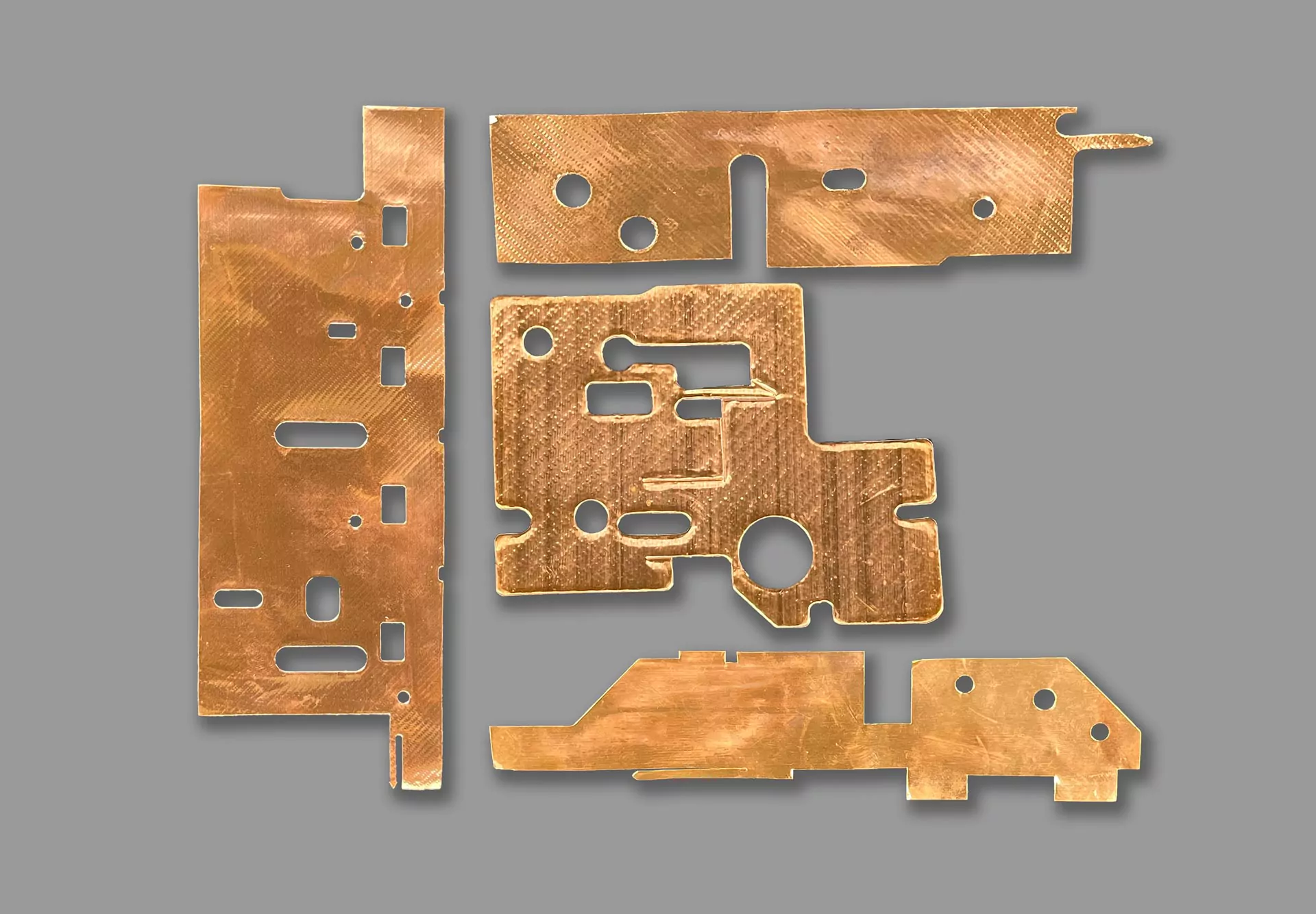

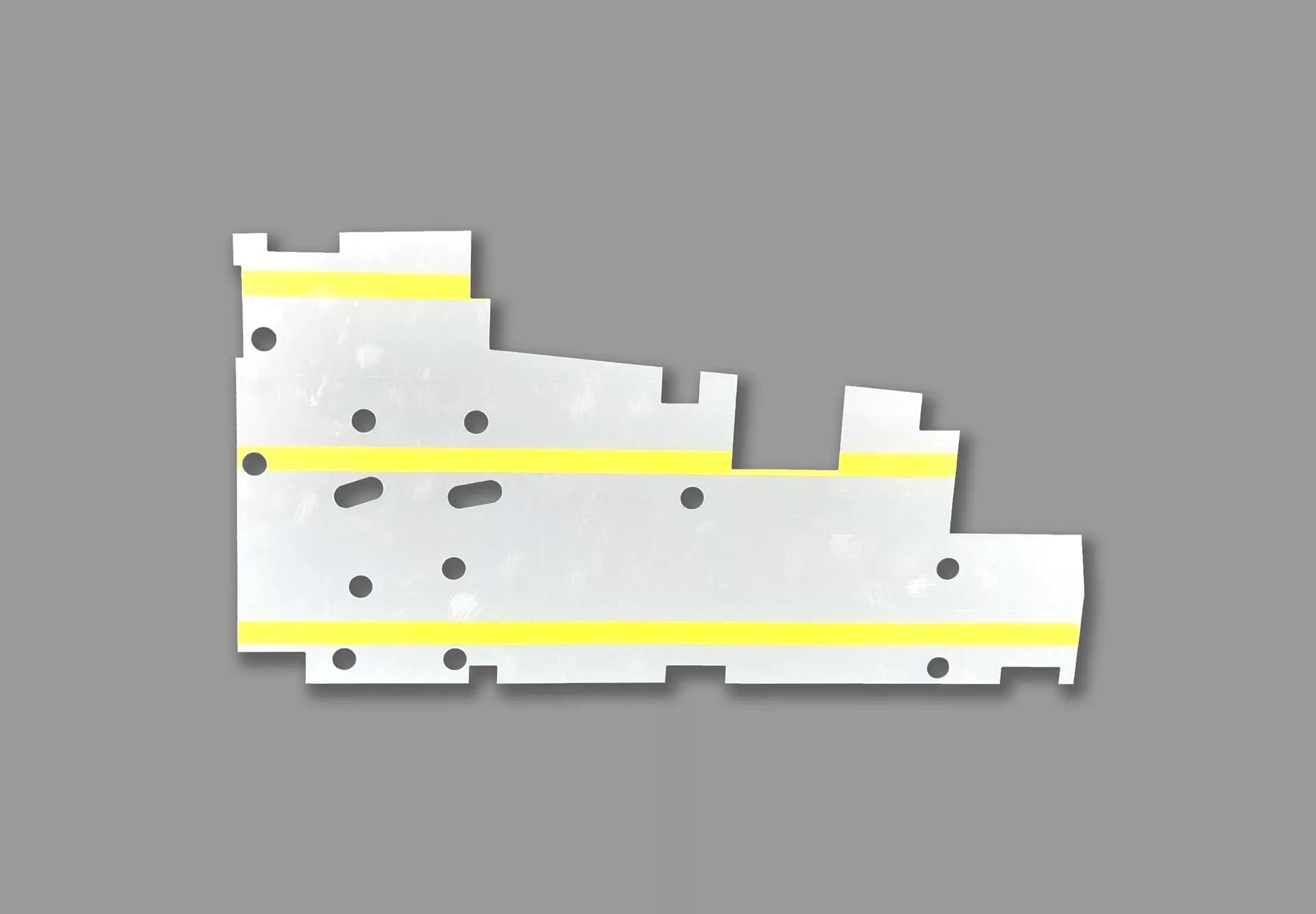

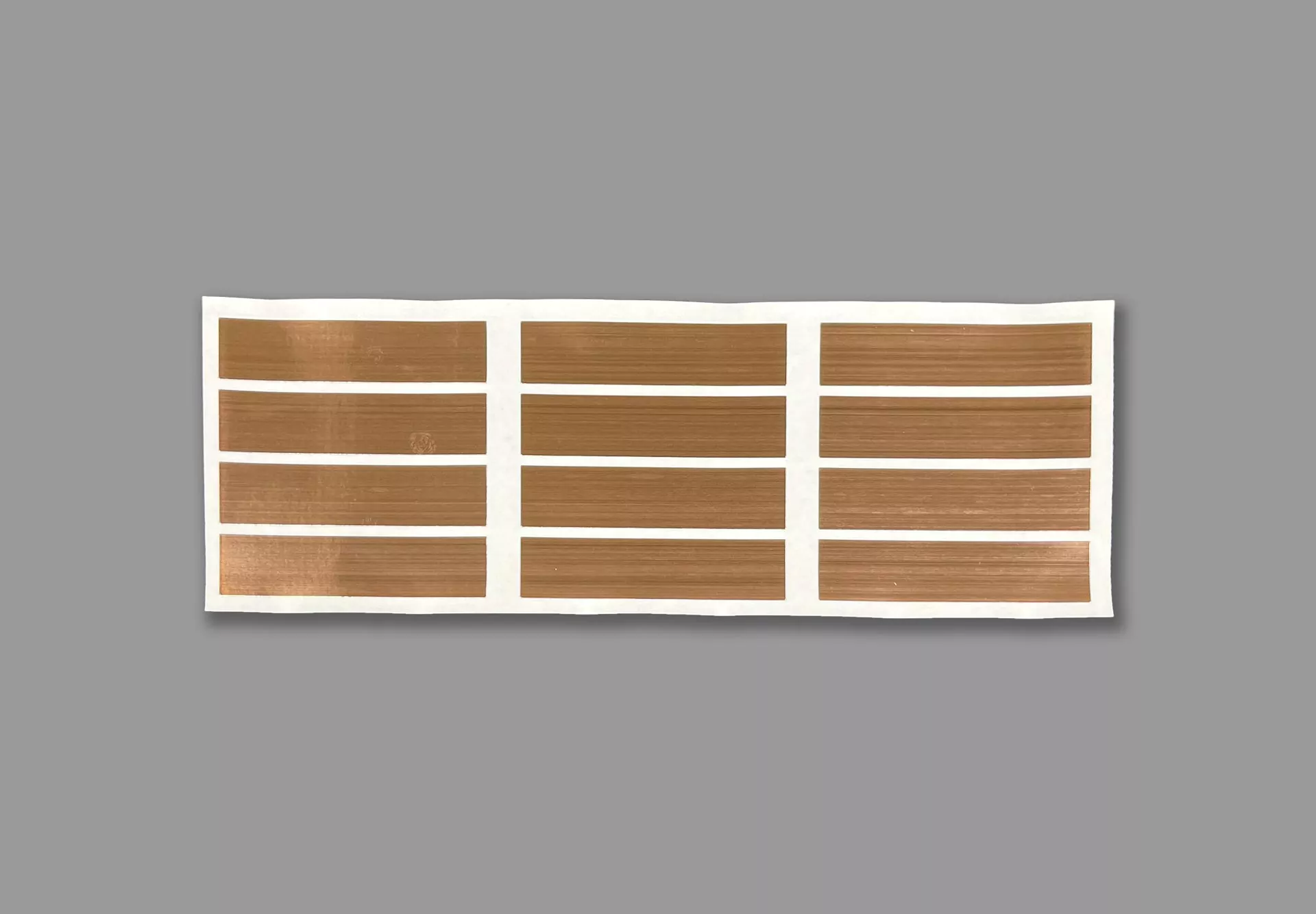

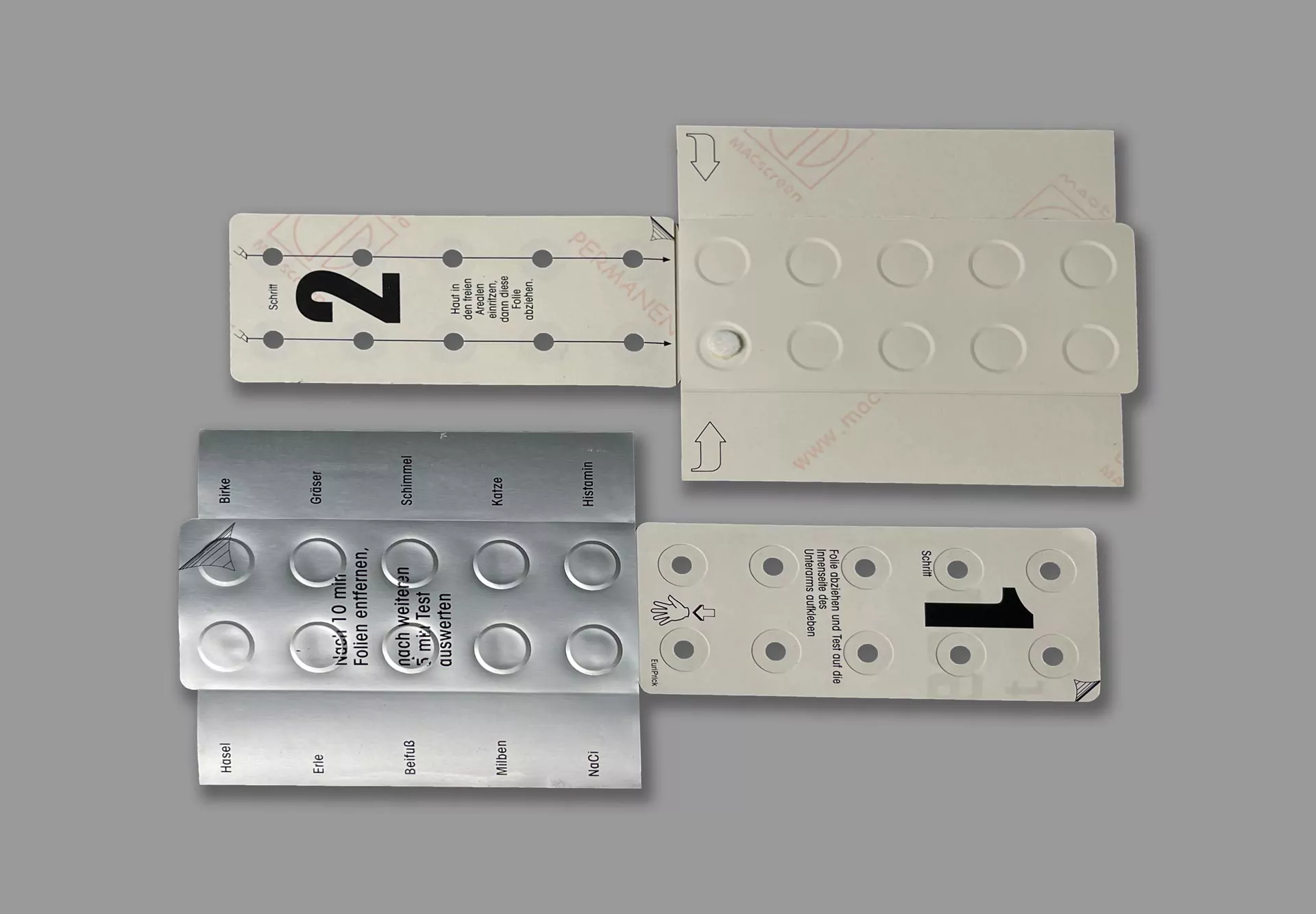

Produce stamped or formed parts using our rotary or stroke stamping processes. These are supplied individually or in rolls, depending on the quantity or tolerances required. Our advanced laminating technology enables a wide variety of materials to be combined and offers maximum flexibility. Our metal foils, including copper and mumetal from flextem, are often used to shield electronic components.

Our experts develop the right cutting tool from strip steel, solid steel or by engraving according to your individual technical requirements, drawings or sketches. For pre-series, prototypes and small quantities, we use plotter technology to offer you customized solutions.

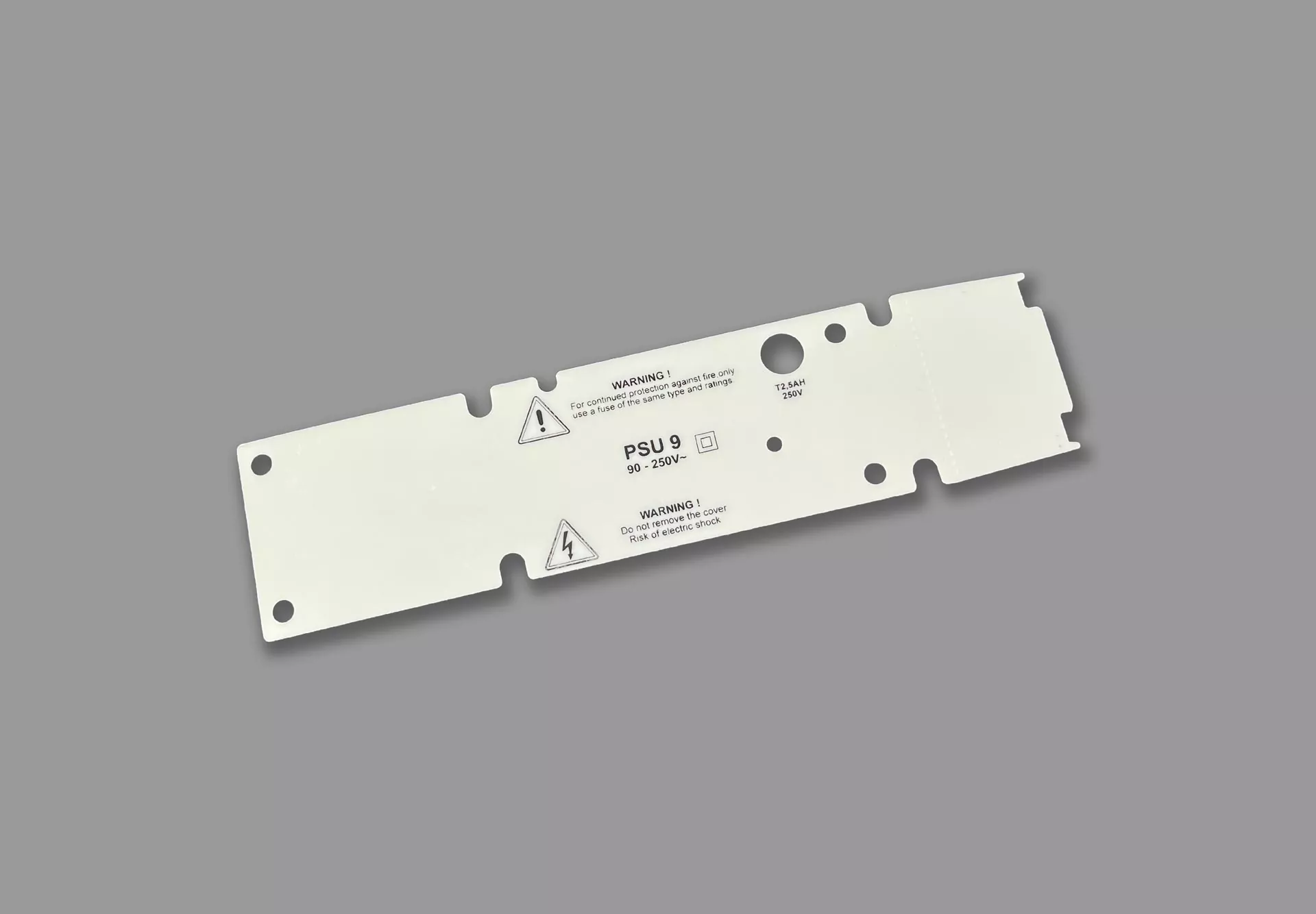

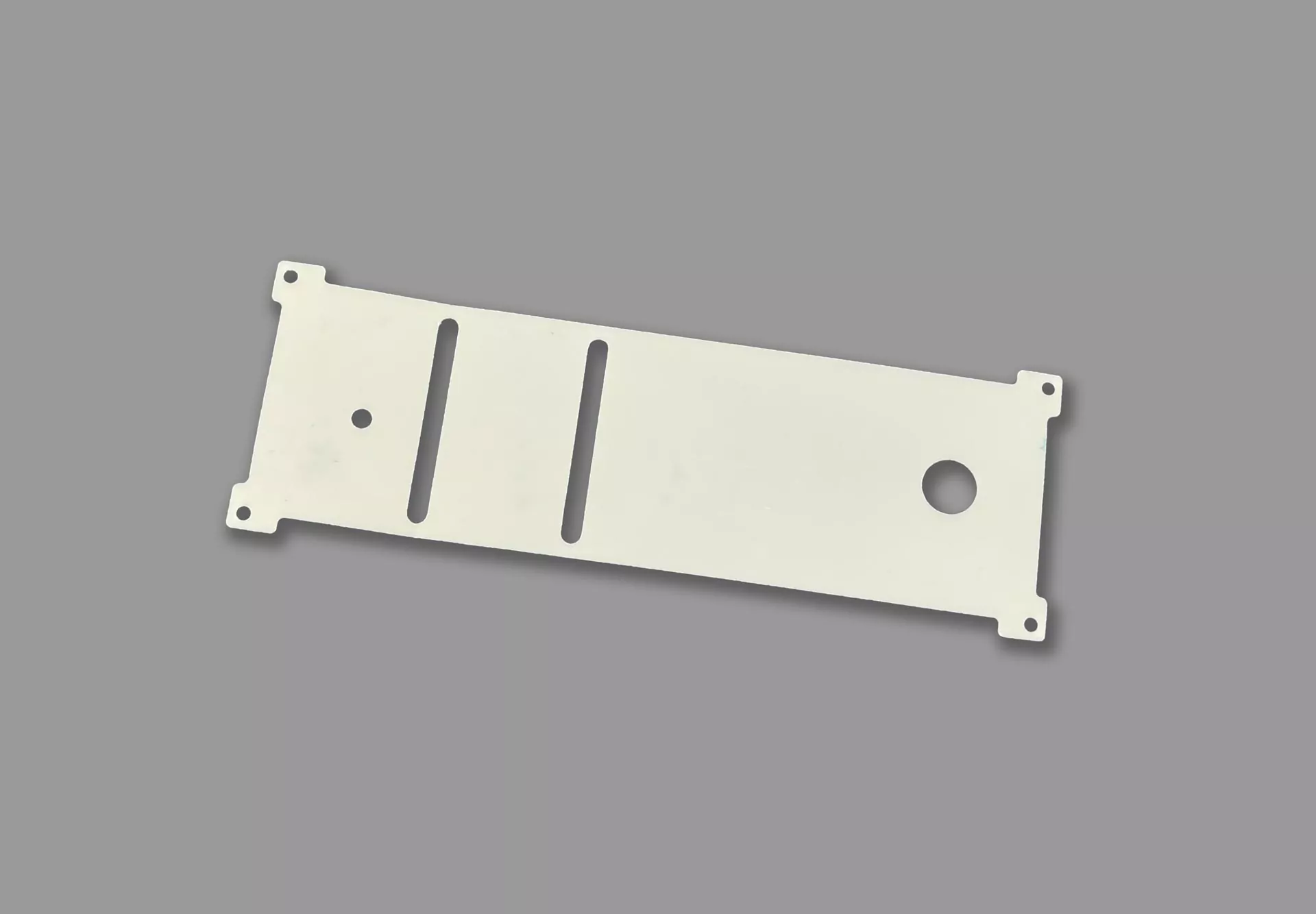

Foil stampings from flextem

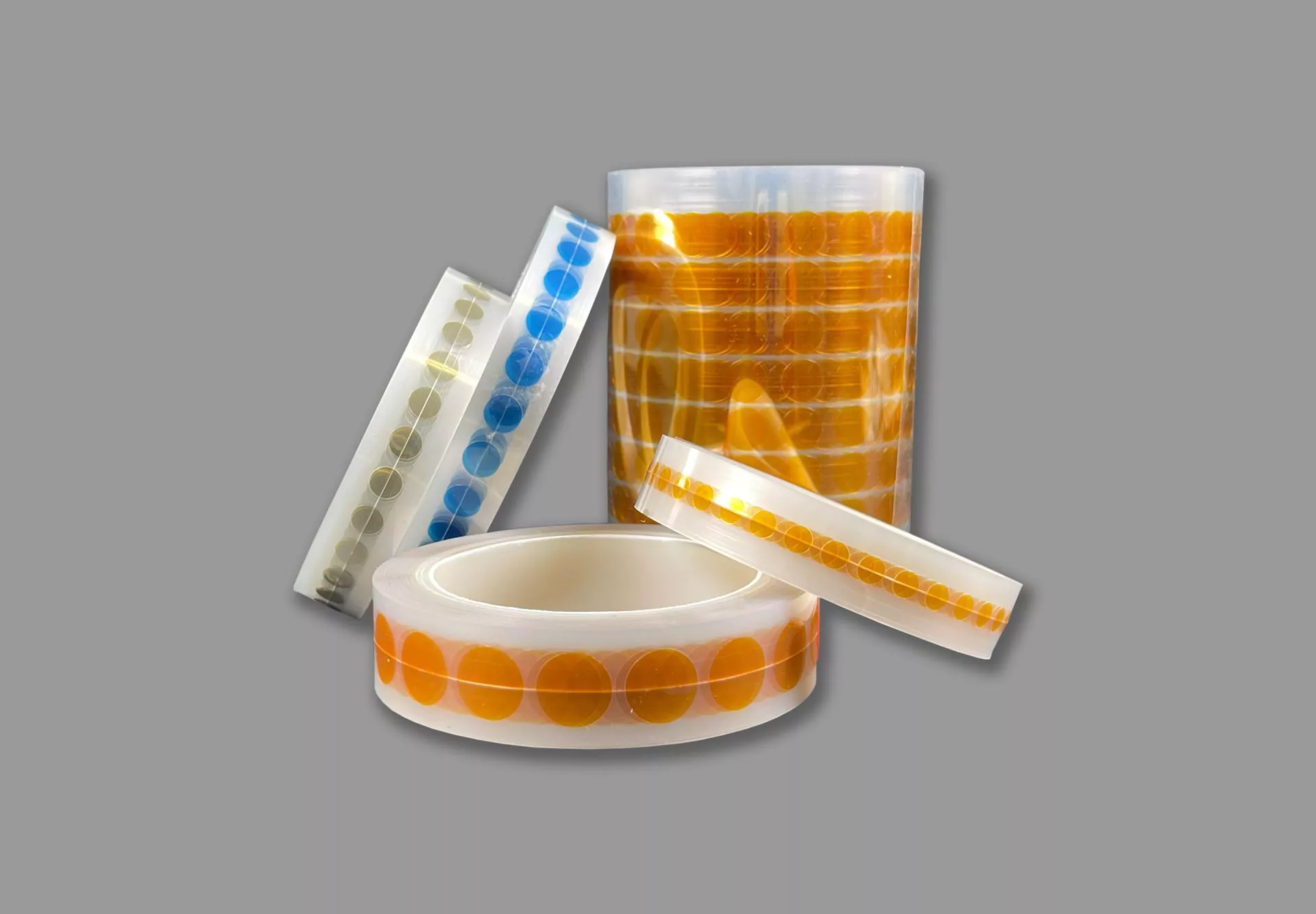

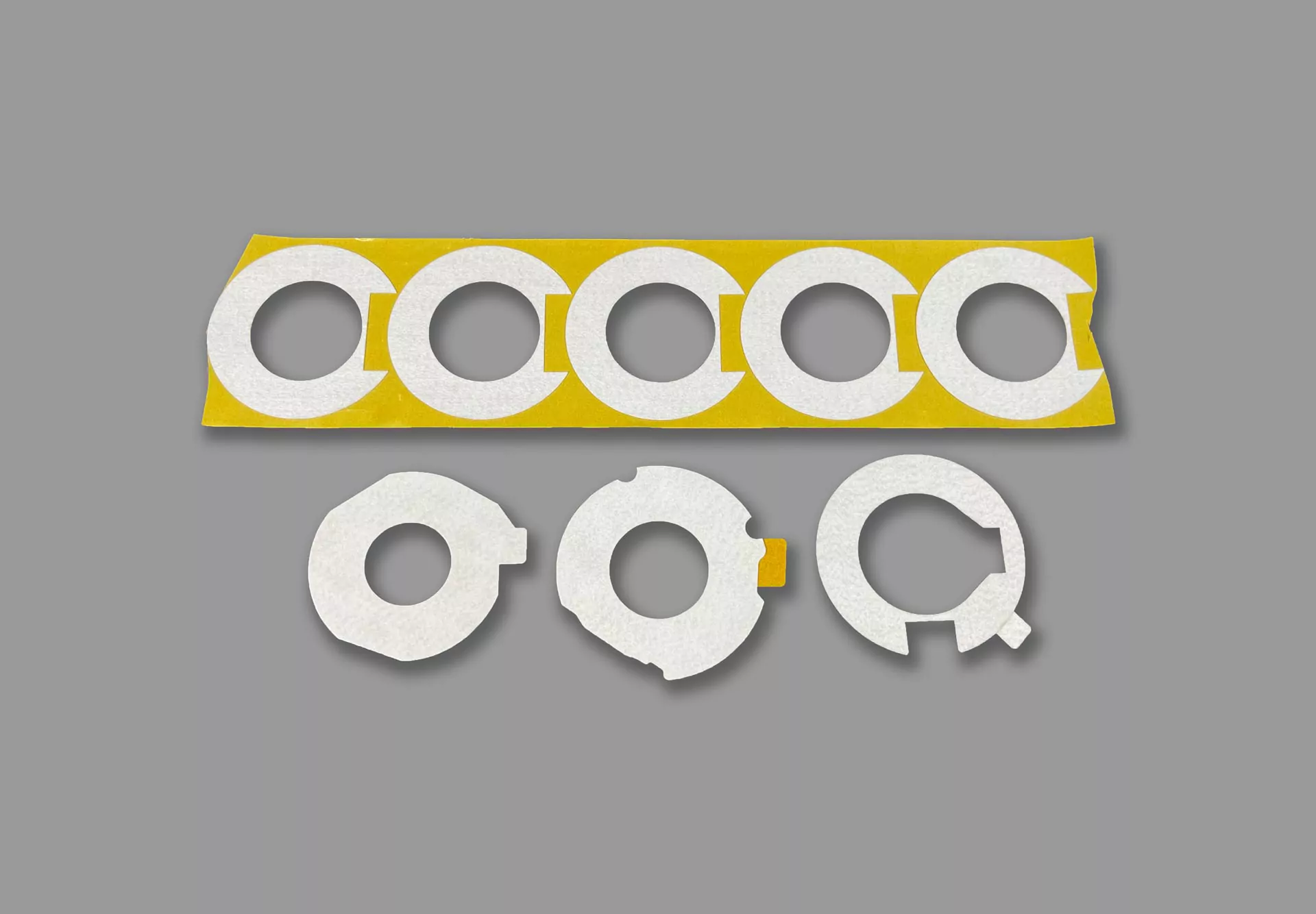

Self-adhesive stamped parts

Foil stampings and molded parts are also supplied according to your individual requirements if required

Foil stampings and molded parts are manufactured according to your individual requirements. Our experienced specialists develop cutting tools from strip steel or solid steel according to the drawings or sketches provided. We also offer the option of producing self-adhesive die-cut parts on silicone paper or siliconized film.

With our rotary or stroke punching processes, we supply punched and formed parts as rolls or individually, depending on the quantity and tolerance requirements. Our advanced laminating technology makes it possible to combine different materials. Metal foils such as copper and mumetal are often used to shield electronic components.