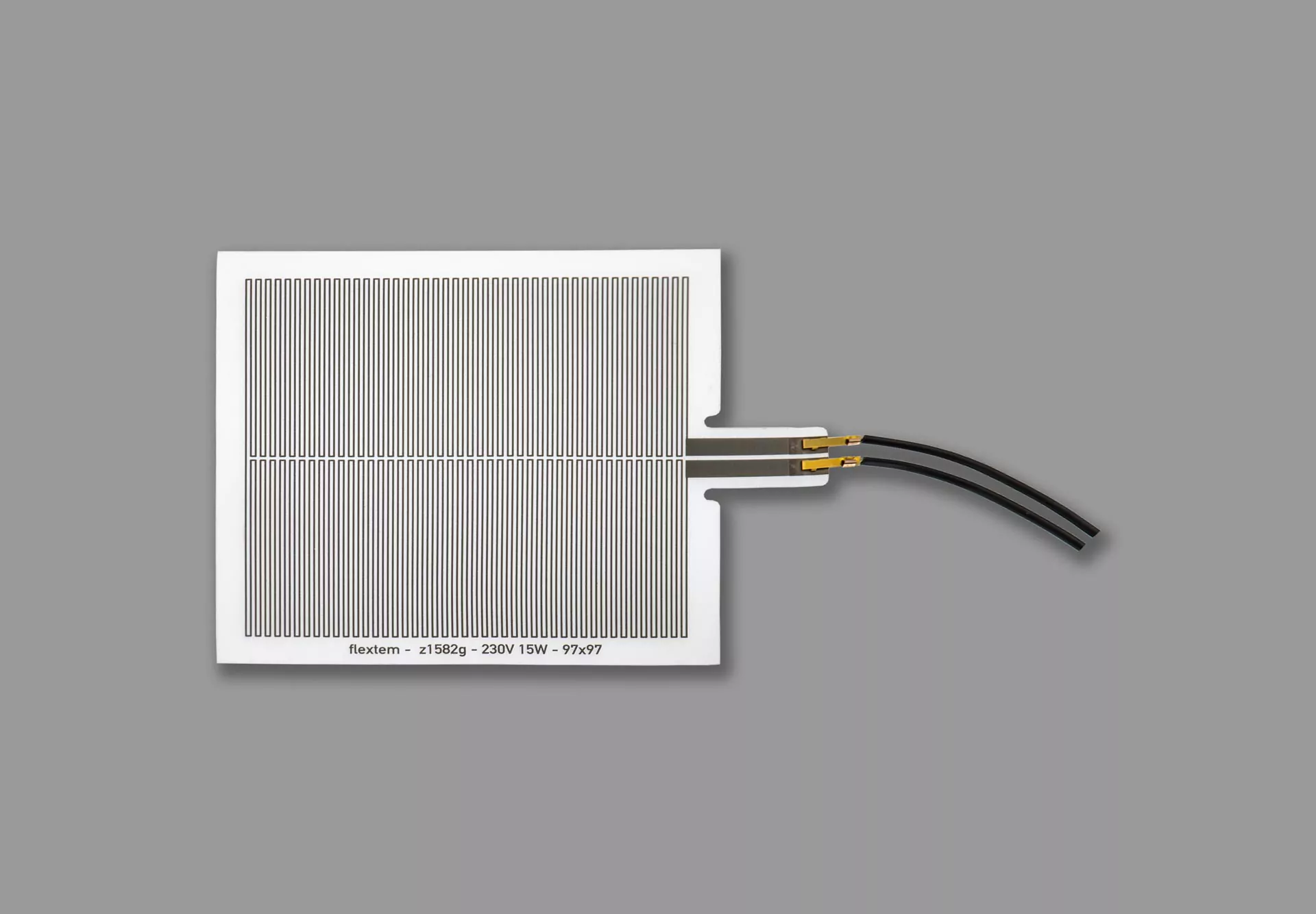

Connection technology

Connection technologies for cables on flexible heating foils: customized solutions for your requirements

The right connection technology plays a decisive role in the integration of flexible heating foils in a wide range of applications. At flextem, we offer a variety of innovative approaches to safely and efficiently connect cables to flexible heating foils to ensure a reliable power supply.

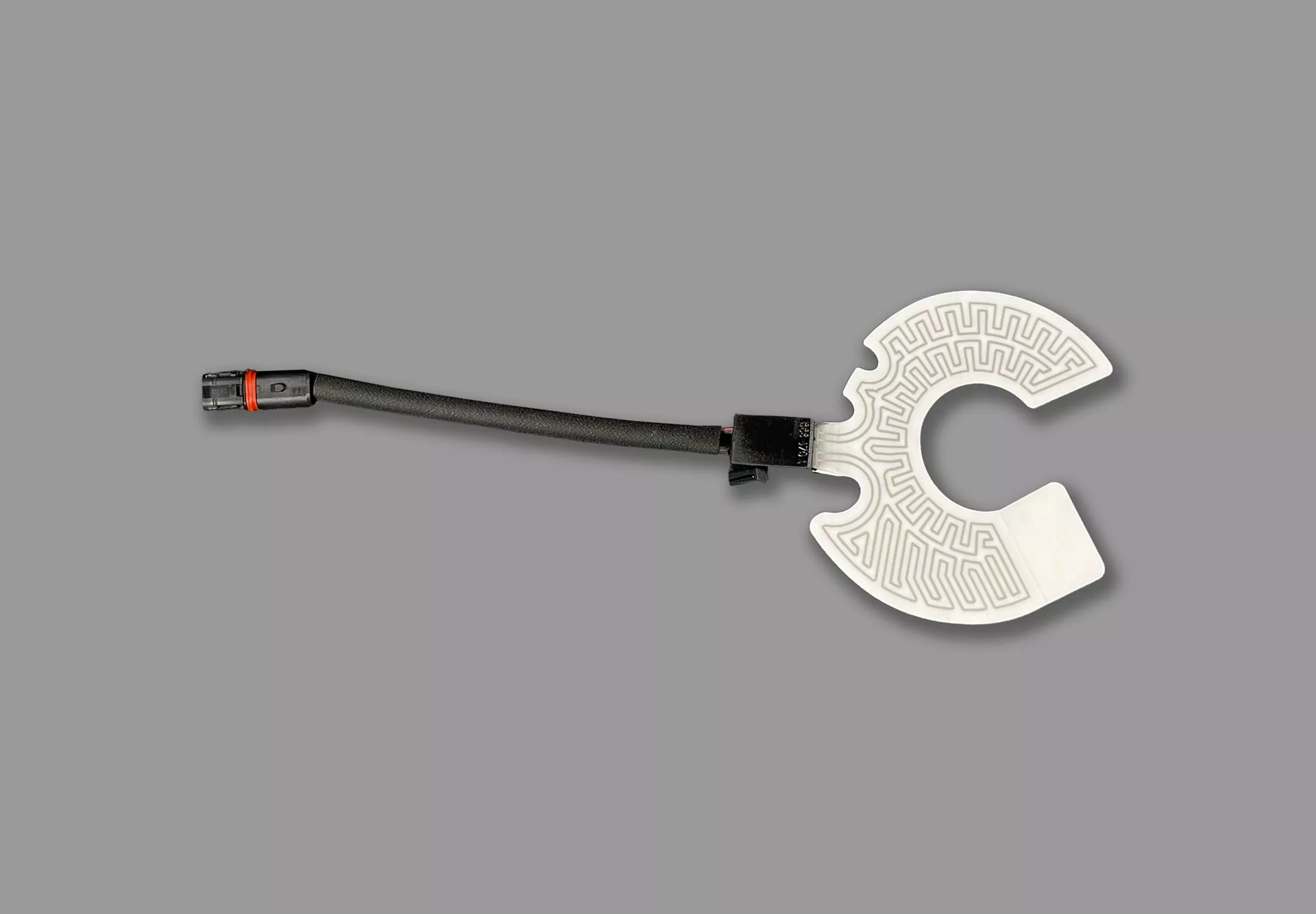

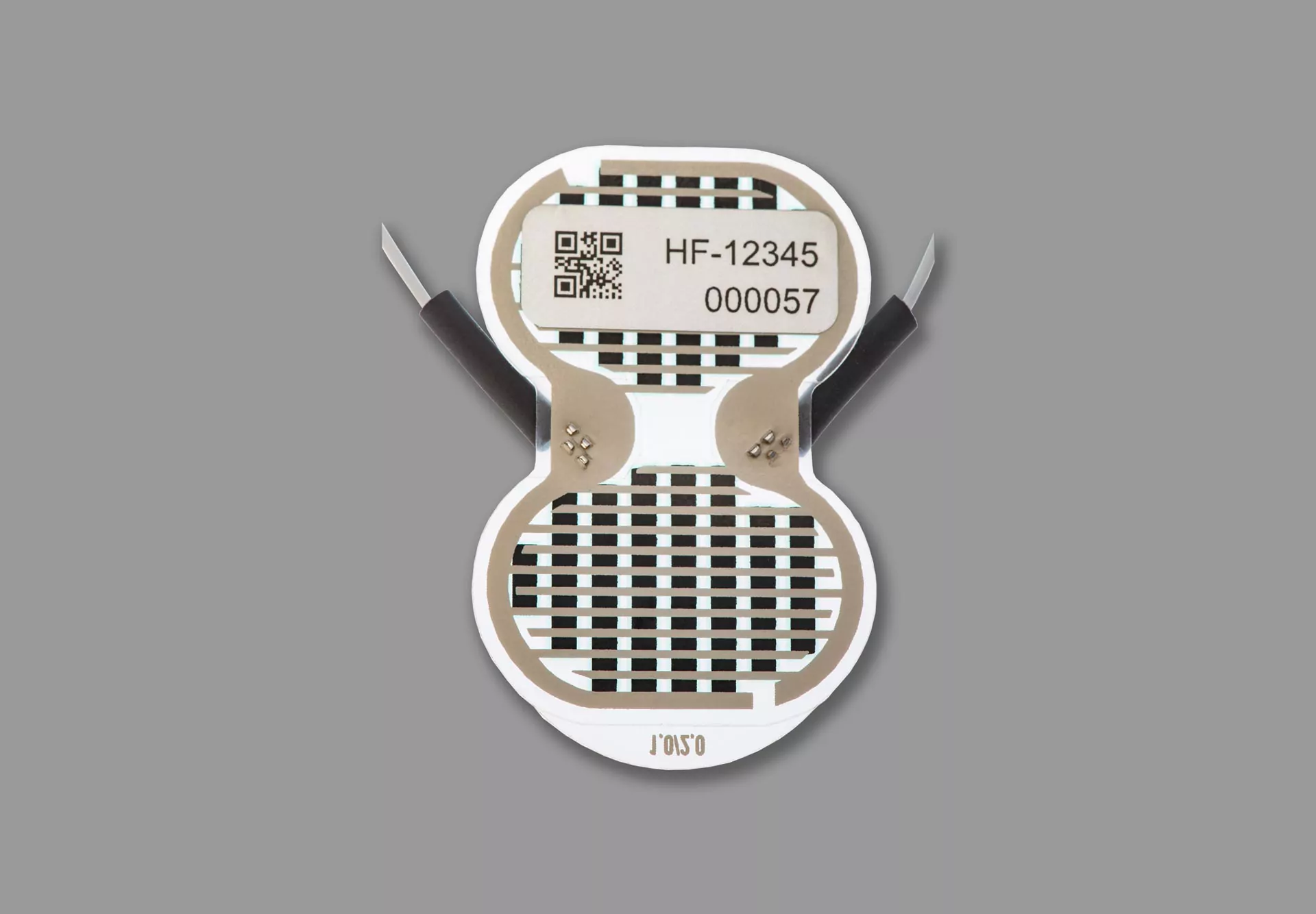

Piercing contact: The piercing contact is an innovative solution for connecting cables safely and effectively to flexible heating foils. This technology enables a contactless connection by piercing the contact through the insulation material of the heating foil. The advantage lies in the minimal impairment of the heating foil structure, which ensures high integrity and reliability of the connection. Piercing contact is particularly useful in applications where maintaining the structural integrity of the heating foil is critical.

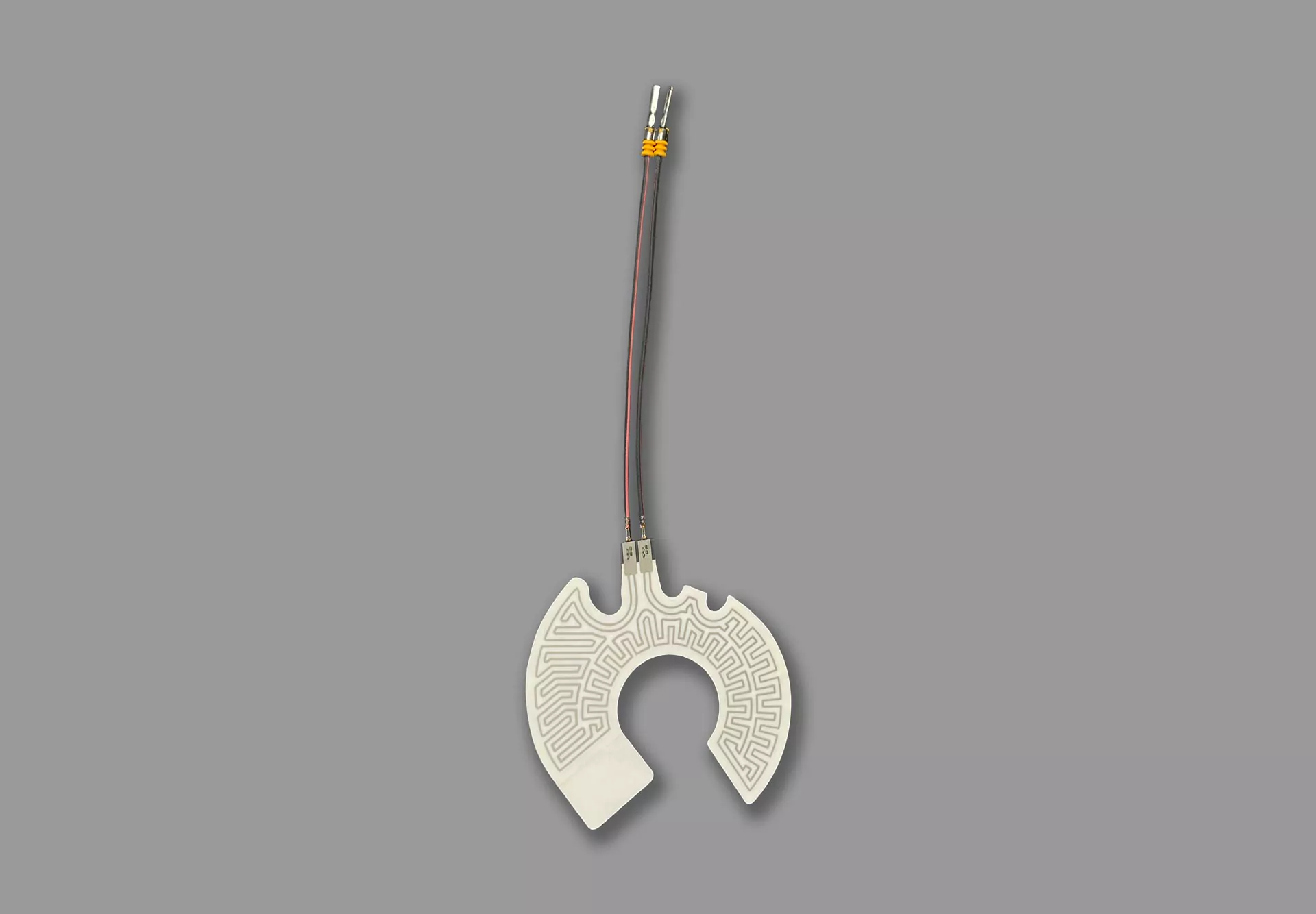

Crimping: Crimping technology offers an efficient way of connecting cables to flexible heating foils. This method enables a fast and reliable connection, whereby the crimp contacts are firmly connected to the cables. This not only ensures good electrical conductivity, but also enables easy installation.

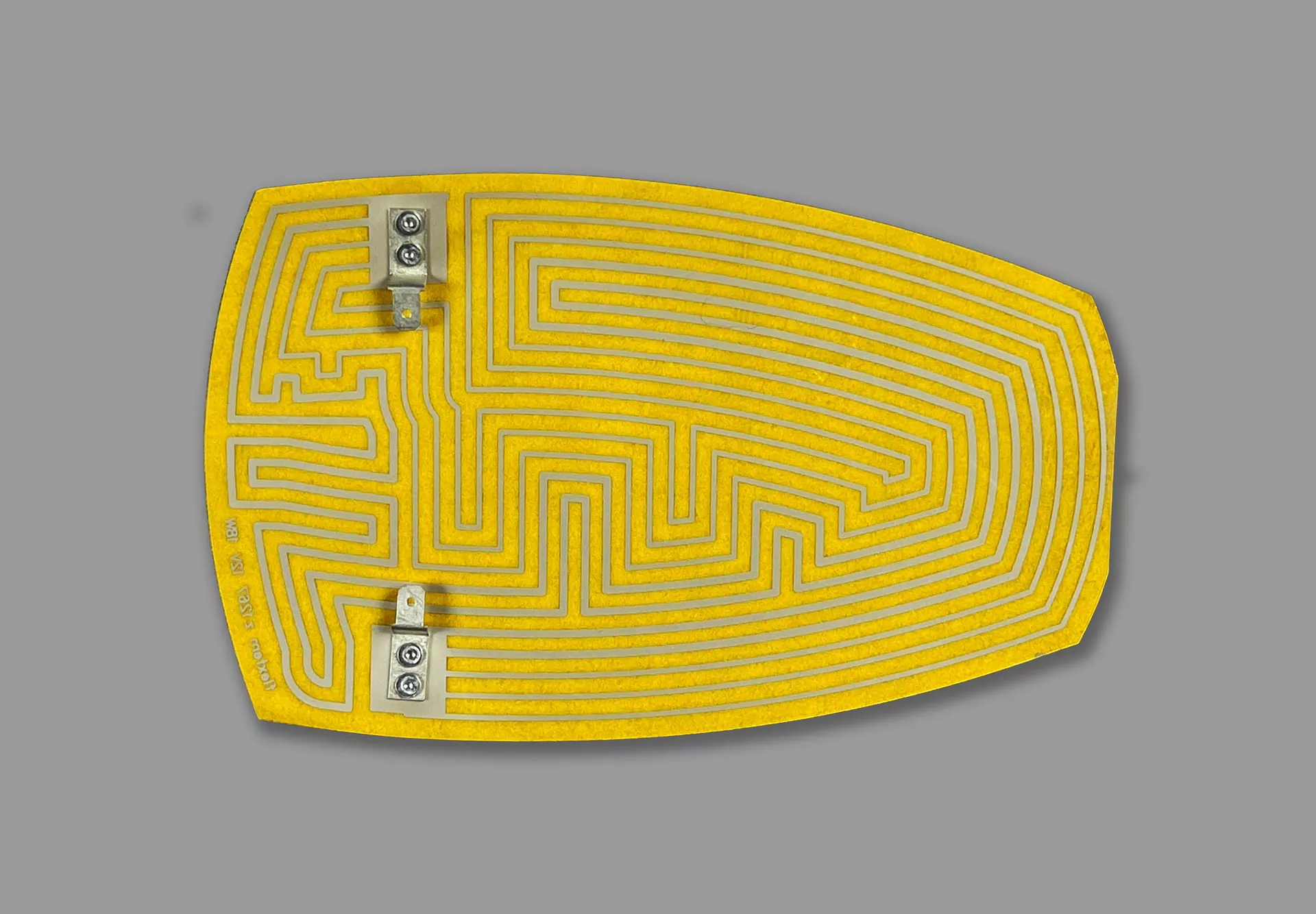

Rivet contact: For applications that require a firm mechanical connection, rivet contacts offer a robust solution for connecting cables to flexible heating foils. These fixed connections are particularly suitable for environments with vibrations or mechanical loads. The high-precision rivet contacts not only ensure a secure electrical connection, but also long-term stability.

Zero-force connector (ZIF): Zero-force connectors, also known as ZIF connectors, offer a sophisticated solution for applications where frequent connection and disconnection operations are required. Thanks to their special design, they enable a secure electrical connection without the application of pressure or force. This is particularly advantageous for sensitive components, as the zero-force connectors guarantee a gentle connection and at the same time ensure reliable electrical conductivity.

Screw contacts: The use of screw contacts offers a reliable and safe way to contact flexible heating foils. This technology enables precise adjustment of the contacting and ensures a strong mechanical connection. Screw contacts are particularly suitable for applications where simple maintenance and uncomplicated replacement of components are required.

Soldering: Soldering the cables to the flexible heating foils is a tried and tested method. This technology not only enables a secure electrical connection, but also ensures high mechanical stability. By using high-quality soldering materials and precise soldering technology, we create connections that can withstand the demanding conditions of industrial environments.

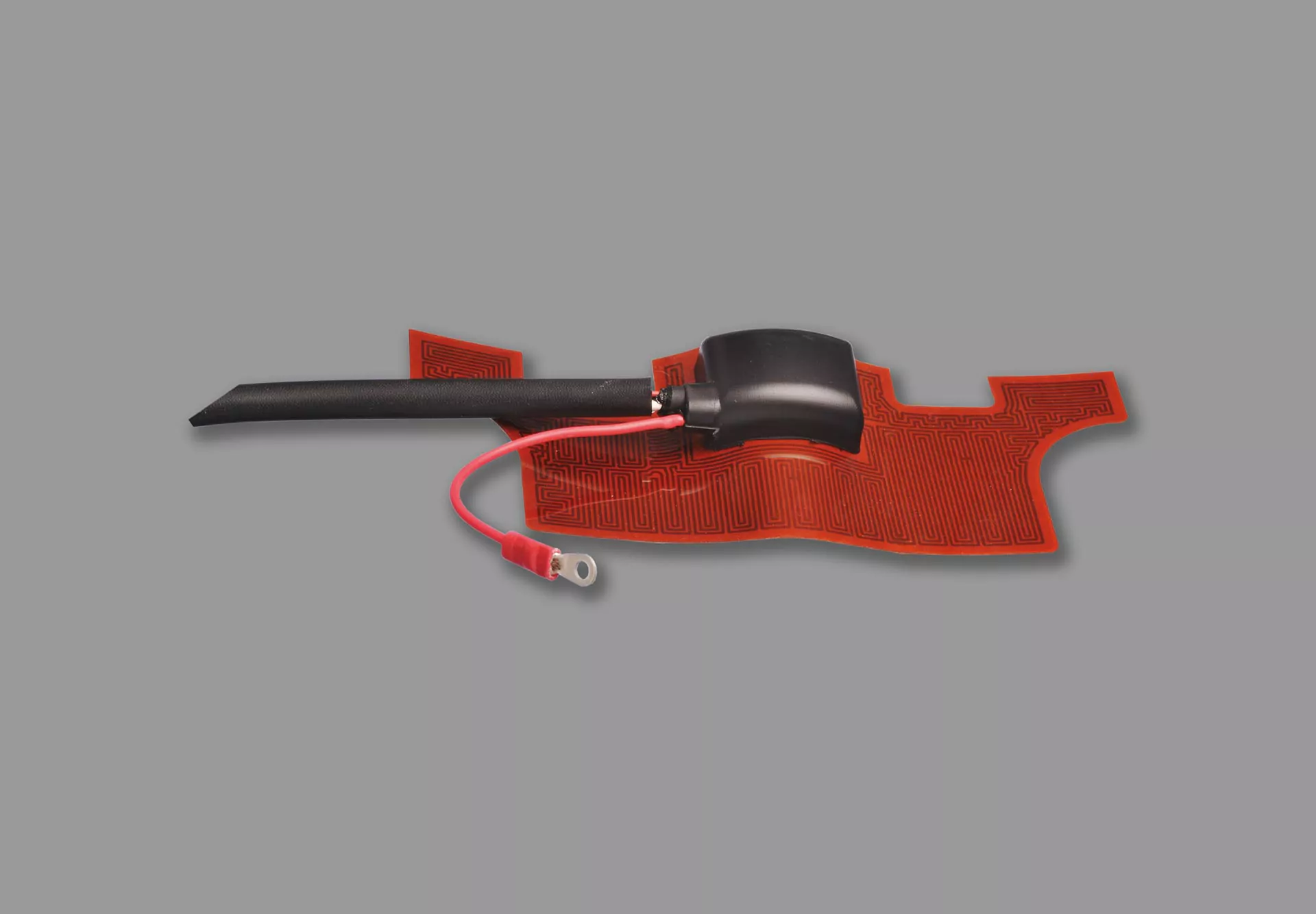

Customized potting based on polyamide (PA)

To provide additional protection for the connections between cables and flexible heating foils and increase their durability, we offer customized potting solutions based on polyamide (PA). This encapsulation creates a robust and insulating layer around the joints, protects against external influences such as moisture and chemicals and thus helps to extend the service life of the heating foils.

We apply the highest quality standards to ensure that your heating foils work reliably and efficiently. Discover the variety of connection technologies and potting options we can offer you and optimize your industrial heating processes. If you have any questions or require further information, please do not hesitate to contact us.